We use cookies to allow our website to work properly, personalize content and advertising, provide social media features and analyze traffic. We also share information about your use of our site with our social media, advertising and analytics partners

Turnkey Solutions

End-to-End Turnkey Solutions

AECA provides end-to-end turnkey manufacturing solutions for customers seeking a reliable production partner from sample production to serial delivery. All manufacturing activities are performed strictly according to customer drawings, specifications, and quality requirements.

By integrating machining, secondary processes, assembly, inspection, and logistics under one controlled workflow, AECA helps customers reduce supplier complexity, control quality risks, and accelerate time-to-market.

AECA Turnkey Capabilities

-

Sample Production (Pre-Series Manufacturing)

Sample production at AECA refers to pre-series manufacturing based on finalized customer drawings , not prototyping or product design.

Samples are manufactured using production-intent materials, processes, machines, and quality controls to ensure full consistency with future serial production.

During this stage, AECA focuses on:

-

Manufacturing samples strictly to customer specifications

-

Validating tolerances, materials, and surface finish requirements

-

Confirming process stability and repeatability

-

Ensuring alignment between sample parts and series production

This approach provides customers with reliable, approval-ready samples and a smooth transition into volume production.

-

-

Precision CNC Machining

Precision CNC machining is the foundation of AECA's turnkey manufacturing solutions.

We manufacture complex components with tight tolerances and consistent quality using advanced CNC equipment.Our machining capabilities support c omplex geometries and demanding dimensional requirements

By keeping machining in-house and integrated into our turnkey workflow, AECA ensures process continuity, stable quality, and efficient scale-up from sample to serial production.

-

Secondary Processes & Surface Treatment

To deliver fully finished parts, AECA manages a wide range of secondary processes and surface treatments as part of our turnkey solutions.

Supported processes include:

-

Anodizing, plating, coating, and heat treatment

-

Deburring, polishing, and surface finishing

-

Marking, engraving, and part identification

All secondary processes are controlled through AECA's quality system to ensure specification compliance, traceability, and consistent appearance across production batches.

-

-

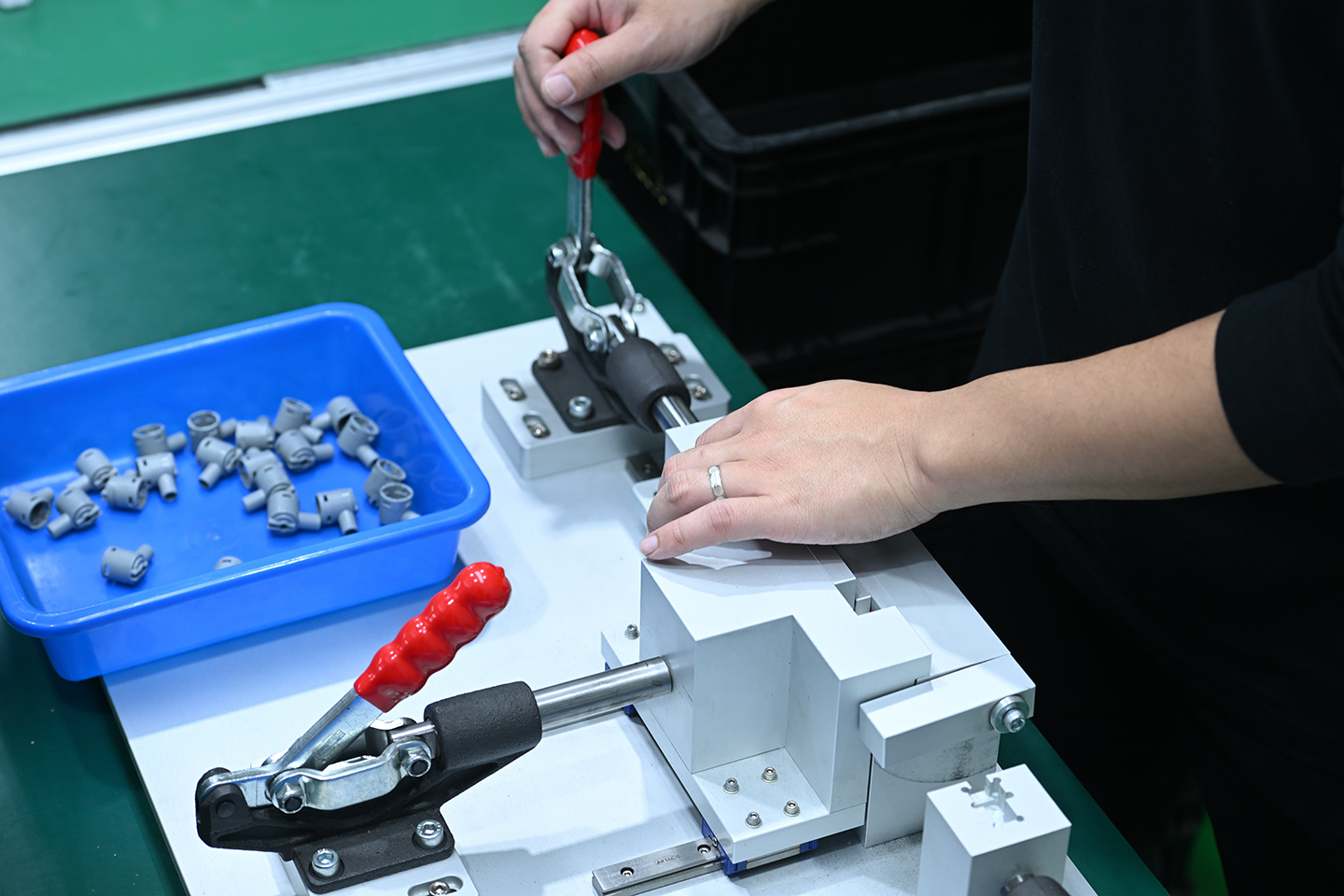

Assembly & Sub-Assembly

AECA offers mechanical assembly and sub-assembly services to deliver ready-to-install components or functional modules.

Assembly services include:

-

Manual and semi-automated assembly

-

Component integration based on customer instructions

-

Functional checks and visual inspections

Combining machining and assembly within one supplier reduces handling risks and provides customers with improved quality control and shorter lead times.

-

-

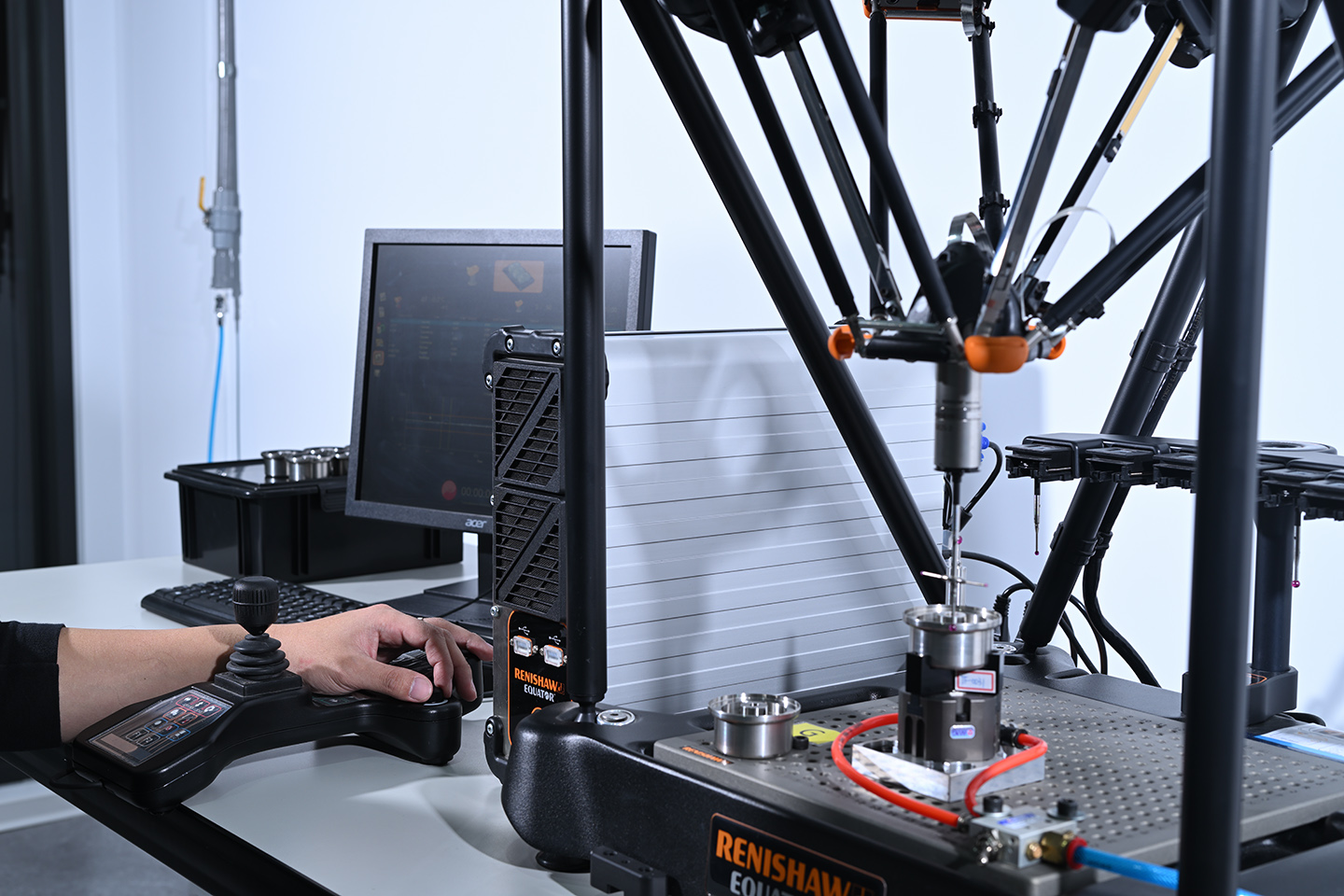

Quality Inspection, Documentation & PPAP

Quality assurance is integrated at every stage of AECA's turnkey manufacturing process to ensure full compliance with customer drawings and specifications.

Our quality capabilities include:

-

In-process and final dimensional inspection using calibrated measuring equipment

-

Controlled inspection plans aligned with customer requirements

-

Inspection records and quality documentation provided upon request

-

PPAP support in accordance with customer-defined requirements

Through structured inspection processes and controlled documentation, AECA supports traceability, consistency, and stable serial production.

-

-

Packaging & Delivery Management

AECA manages packaging and delivery coordination to ensure products arrive protected, identified, and on schedule.

Our logistics support includes:

-

Custom packaging according to customer requirements

-

Labeling and product identification

-

Coordinated domestic and international shipments

Customers benefit from receiving production-ready parts without the need to manage multiple suppliers.

-