We use cookies to allow our website to work properly, personalize content and advertising, provide social media features and analyze traffic. We also share information about your use of our site with our social media, advertising and analytics partners

CNC Machining

Multi-Axis Milling and Turning

Our multi-axis milling and turning capabilities enable complex parts to be machined in fewer setups with greater control. This approach improves dimensional accuracy, repeatability, and process stability while supporting tight tolerance requirements.

Materials We Work With

- Metals - a wide range of industrial metals (titanium, brass/bronze, stainless steel, carbon steel, aluminum/aluminum alloys)

- Casting Materials

- Forging Materials

Sample & Production Runs

Tight Tolerances & Surface Finish

We achieve tight tolerances and stable surface finishes through advanced CNC equipment and controlled machining processes. Each part is produced to precise specifications to ensure dimensional accuracy and functional reliability.

High-Precision CNC Machining Services for Global OEMs

AECA provides custom CNC machining services designed to support customers. With advanced multi-axis machining centers, experienced in-house engineering teams, and ISO-certified quality systems, we help our partners achieve consistent accuracy, stable quality, and dependable lead times for critical components.

With manufacturing facilities in Taiwan and Thailand, AECA supports global customers with cost-effective, high-precision CNC machining solutions for demanding applications.

Why Choose AECA for CNC Machining?

-

Tight Tolerance & Precision CNC Machining

Our CNC machining processes are optimized to achieve tight tolerances, excellent surface finishes, and high repeatability for complex metal components. -

Engineering-Driven Manufacturing Support

Our in-house engineers provide DFM (Design for Manufacturability) consultation and technical reviews to reduce cost, prevent production issues, and improve overall part performance. -

Scalable CNC Machining from Sample to Mass Production

From rapid prototyping to long-term production programs, AECA delivers scalable CNC machining solutions that grow with your business. - Flexible to Your Requirements

At AECA, we adapt to your needs by acting as a manufacturing partner, not just a supplier. Our team adjusts processes, capacity, and support to ensure your project moves forward efficiently and reliably. -

ISO-Certified CNC Machining Manufacturer

AECA operates under ISO 9001 , IATF 16949 , and ISO 13485 quality management systems, ensuring controlled processes, traceability, and consistent quality.

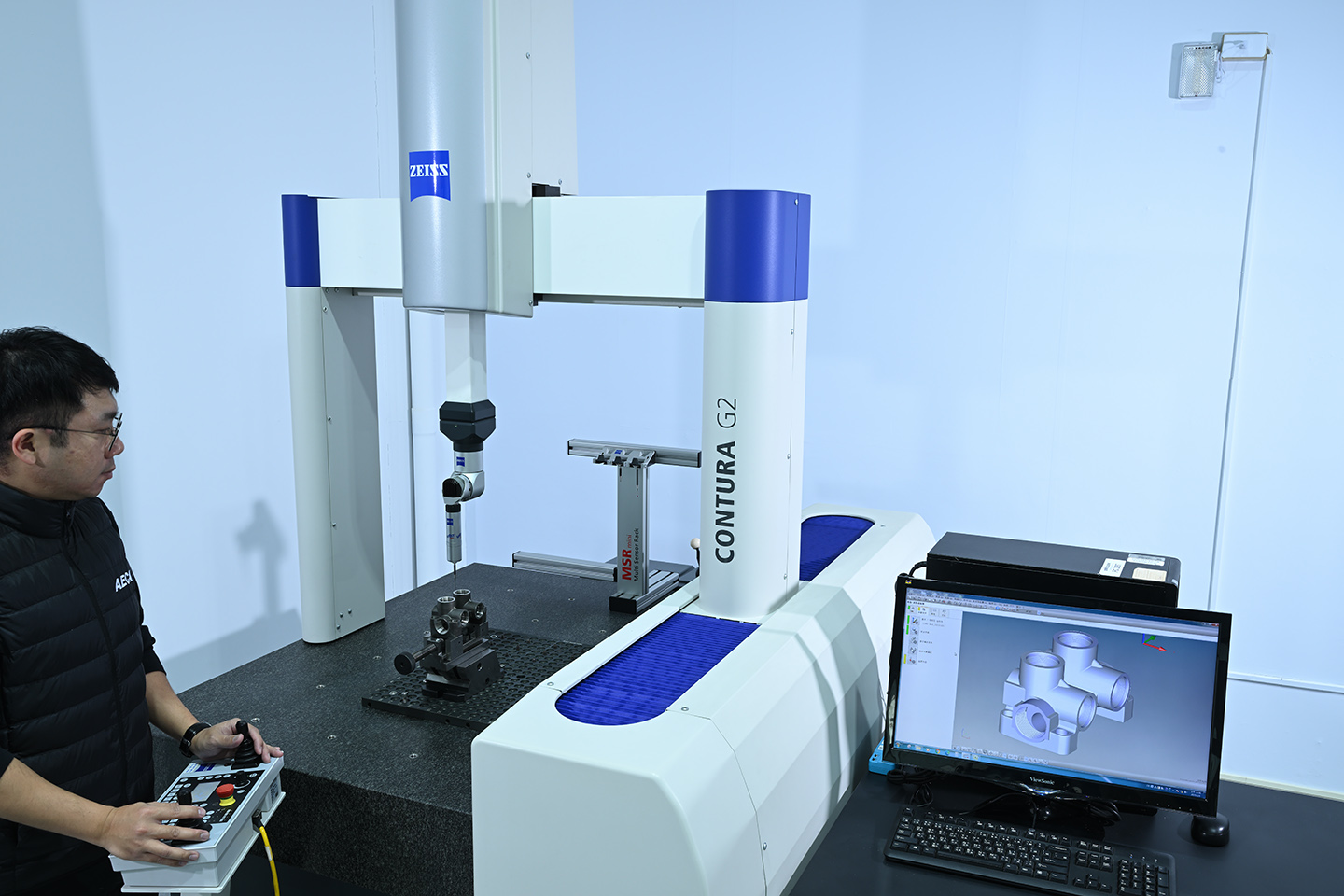

Quality Assurance & Inspection for CNC Machining

Quality control is fully integrated into our CNC machining services:

-

First Article Inspection (FAI)

-

In-process dimensional inspections

-

Coordinate Measuring Machine (CMM) inspection

-

Traceable inspection records and reports

-

Regular calibration of measurement equipment

Our inspection processes ensure every CNC machined part meets drawing specifications and customer requirements.

AECA is committed to excellence in every CNC machining project:

-

ISO 9001: Quality management system

-

IATF 16949: Automotive quality management

-

ISO 13485: Medical device manufacturing

We implement in-process and final inspections , dimensional verification with CMMs and Renishaw measurement systems, and complete traceability for all parts.