Strategic Insights from Our Visit to MAZAK: Advancing AECA’s Automation Vision

AECA Strengthens Smart Manufacturing Capabilities with MAZAK Factory Visit

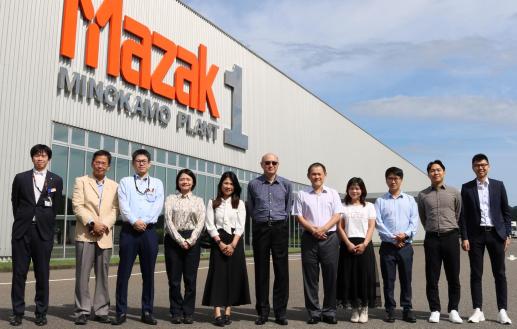

As part of AECA’s ongoing commitment to precision, efficiency, and innovation, our team recently visited the MAZAK factory to explore the future of automated production. The visit served two key purposes: finalizing the procurement of advanced multi-tasking machines and gaining deeper insights into MAZAK’s production philosophy, quality systems, and automation strategies.

Advancing with Next-Generation CNC Technology

During the visit, we observed the MULTIPLEX W-200Y CNC machine in action. Its dual-spindle, dual-turret configuration enables simultaneous machining, reducing cycle times and boosting throughput. With synchronized spindles, Y-axis capability, and MAZAK’s Smooth Technology control system, the machine is ideal for complex part geometries and high-mix, low-volume production—making it highly relevant to AECA’s aerospace and medical component lines.

Exploring Automation Potential

Beyond the machines, MAZAK demonstrated its modular automation systems, integrating gantry loaders, robotic arms, and centralized controls. These scalable solutions provided a blueprint for AECA’s automation roadmap, including automated material handling, in-process inspection, and real-time data feedback—steps toward a fully connected and autonomous production ecosystem.

Insights into Quality and Culture

MAZAK’s quality assurance framework, supported by digital traceability and an in-house MES (Manufacturing Execution System), ensures precision at every stage. Equally impressive is the company’s culture of continuous improvement (Kaizen) and employee training, which fosters innovation and discipline on the factory floor.

Planning AECA’s Future Layout

Inspired by these insights, AECA has begun planning its future production layout with a focus on:

- Cellular Manufacturing – grouping machines by product families to reduce movement and improve efficiency

- Automated Material Flow – implementing AGVs and conveyor systems for streamlined logistics

- Digital Integration – expanding IIoT applications for predictive maintenance and energy monitoring

- Scalable Automation Modules – creating flexible zones to accommodate future upgrades

A Step Toward a Smarter Future

This visit marks a pivotal step in AECA’s transformation, as we invest not only in advanced machines but also in building a smarter, more resilient production future.