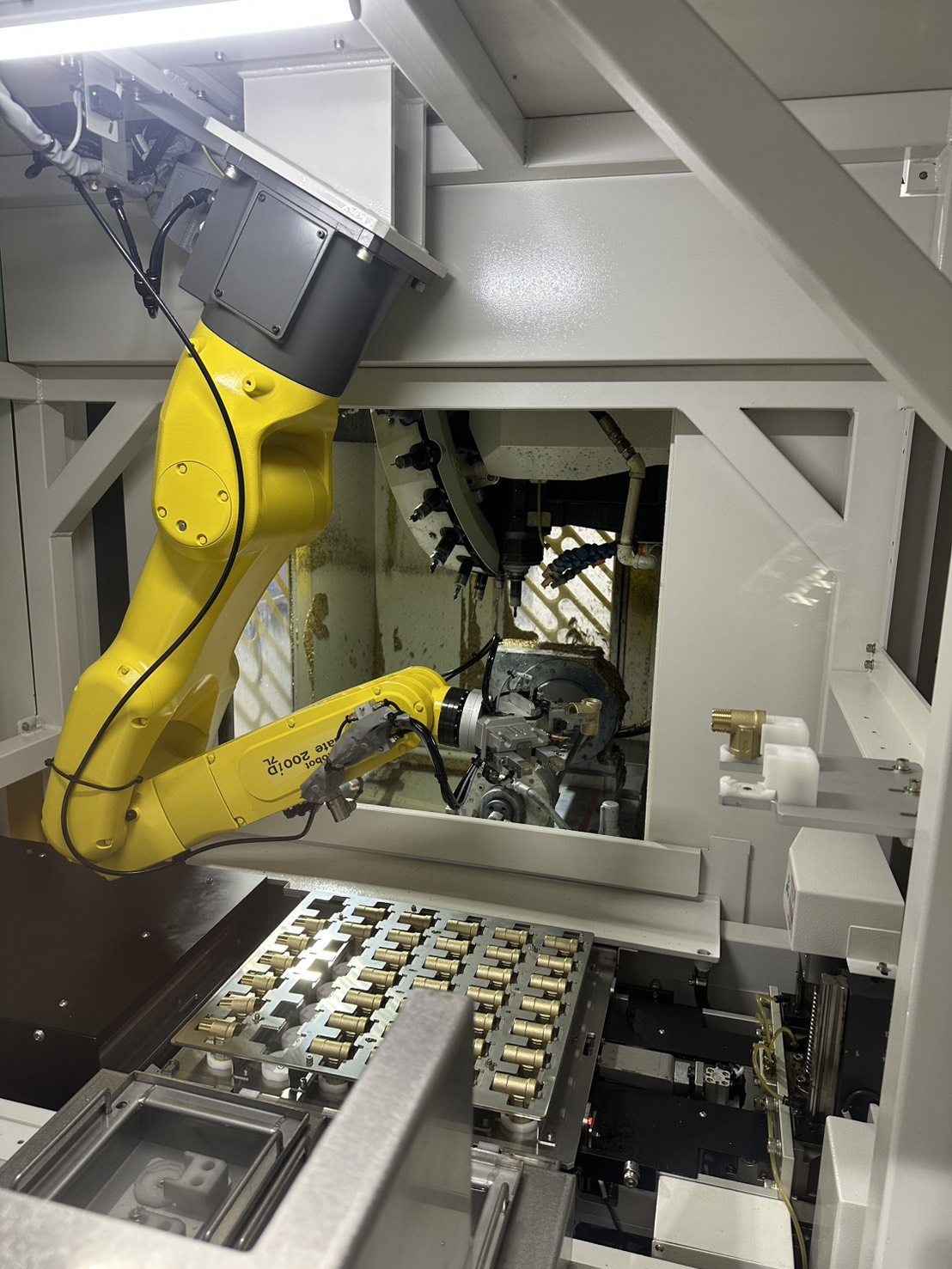

Automated production connection

AECA Factory Achieves Full Automation with FANUC-Integrated Production Line

AECA is proud to announce the successful deployment of a fully automated production system, seamlessly integrated with FANUC CNC machining centers. This advanced setup enables continuous 24-hour unmanned operation, significantly enhancing throughput, consistency, and traceability.

The system architecture includes:

• Automated Material Handling: Raw materials are retrieved and loaded via robotic arms and conveyor systems, eliminating manual intervention.

• Post-Processing Integration: Components undergo in-line cleaning, air drying, and surface preparation without leaving the automated cell.

• Quality Control Automation: At scheduled intervals, the system performs sample extraction and inspection using vision sensors and measurement tools, ensuring compliance with dimensional and surface standards.

• Centralized Control System: All modules are connected to a unified MES (Manufacturing Execution System), enabling real-time monitoring, data logging, and adaptive scheduling.

This milestone reflects AECA’s commitment to smart manufacturing and Industry 4.0 principles, positioning us to deliver higher precision, faster turnaround, and more sustainable operations.