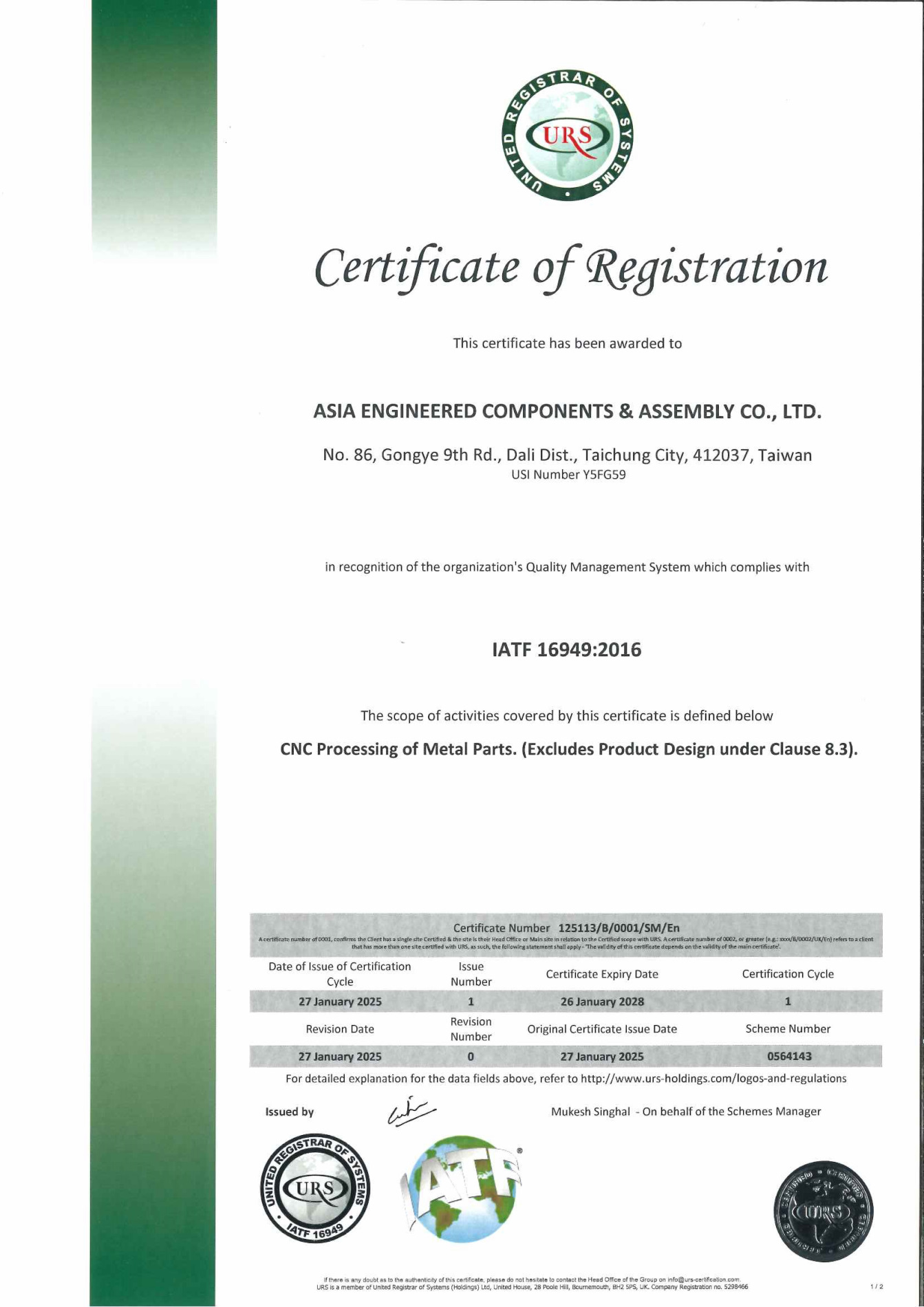

What is the IATF 16949 Standard for Automotive Suppliers?

IATF 16949 is a quality management system standard developed by the International Automotive Task Force (IATF) to harmonize automotive-specific requirements across global supply chains. It builds upon ISO 9001 but adds automotive-focused processes such as advanced product planning, failure mode prevention, and process control to ensure zero-defect production.

The standard applies to OEMs and Tier 1–2 suppliers in the automotive industry, ensuring that components meet both customer and regulatory expectations .

Key IATF 16949 Requirements

- Advanced Product Quality Planning (APQP)

- Production Part Approval Process (PPAP)

- Failure Mode and Effects Analysis (FMEA)

- Statistical Process Control (SPC)

- Corrective and preventive action (CAPA)

- Process monitoring, measurement, and continuous improvement

These requirements ensure automotive components are manufactured consistently, safely, and with minimal defects, meeting both OEM and regulatory standards.

How AECA Applies IATF 16949 Standard

- Advanced Product Quality Planning (APQP) for all automotive components

- Production Part Approval Process (PPAP) submission and management for OEM compliance

- Strict process control and statistical monitoring (SPC)

- First Article Inspection (FAI) and inspection records

- Supplier evaluation and quality assurance

- In-process inspections and final verification using calibrated equipment

- Continuous improvement programs based on production data and corrective actions

This approach ensures that AECA consistently delivers high-quality automotive components to OEMs and Tier 1-2 suppliers worldwide.

Ensuring Product Quality

-

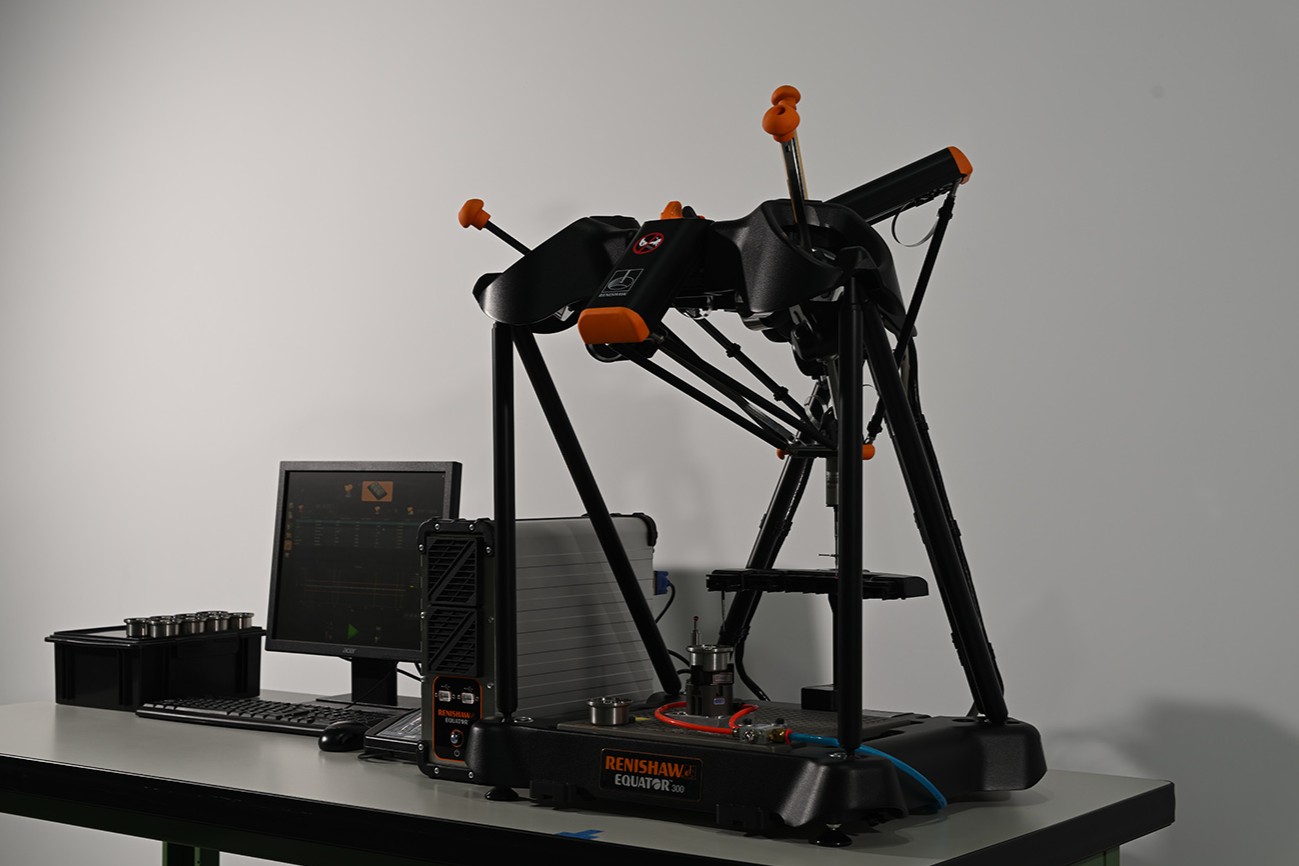

Inspection, Measurement & Traceability

AECA's inspection and measurement processes are controlled under our IATF 16949 quality management system.

Capabilities include:

-

In-process and final dimensional inspection

-

Renishaw inspection systems and calibrated measuring equipment

-

Lot and batch traceability

-

Inspection record retention and documentation control

These measures help ensure automotive components meet specification requirements and support effective issue containment when necessary.

-

-

Production Traceability & Quality Control

Traceability and quality control are essential for automotive manufacturing. AECA implements:

-

Material and production lot identification

-

Clear segregation and control of non-conforming products

-

Documented corrective actions to prevent recurrence

-

Ongoing monitoring of production performance

This approach supports reliable supply, consistent quality, and long-term automotive partnerships.

-