AECA Precision Machining, Intelligent Inspection, and Global Solutions

Setting the Standard for Quality

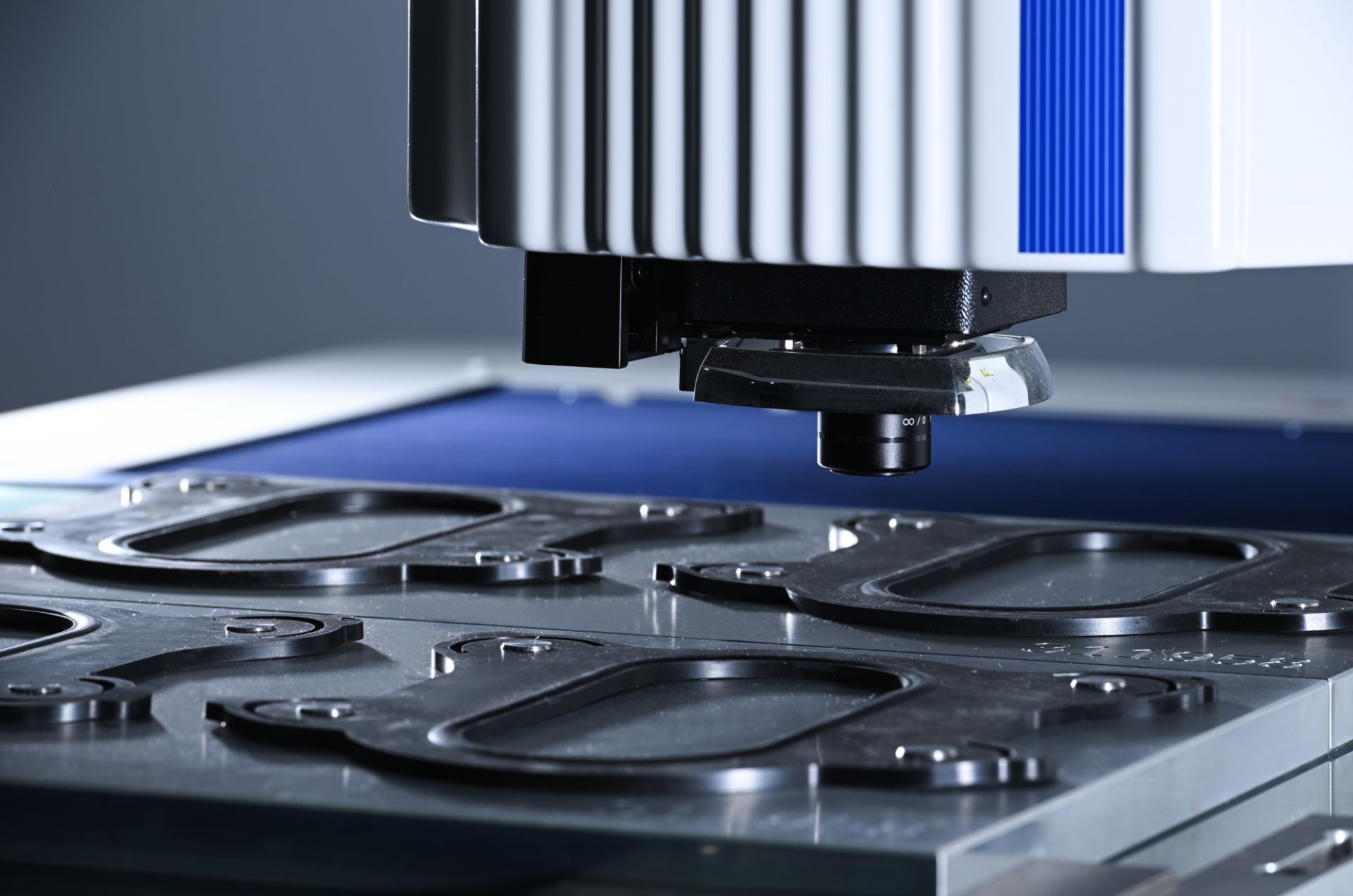

Established the A-One Automated Inspection Center to ensure every product complies with client and industry standards.

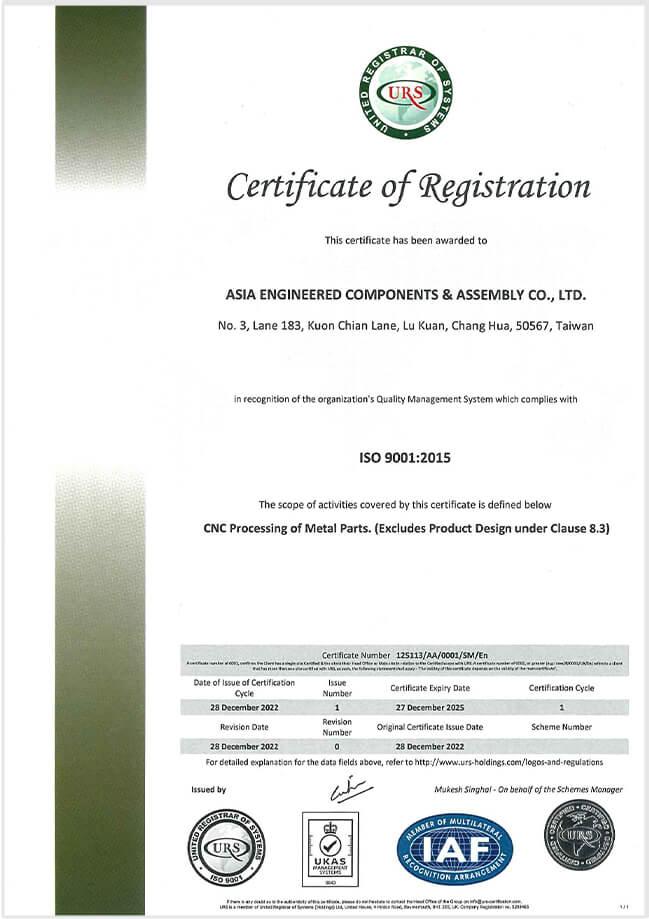

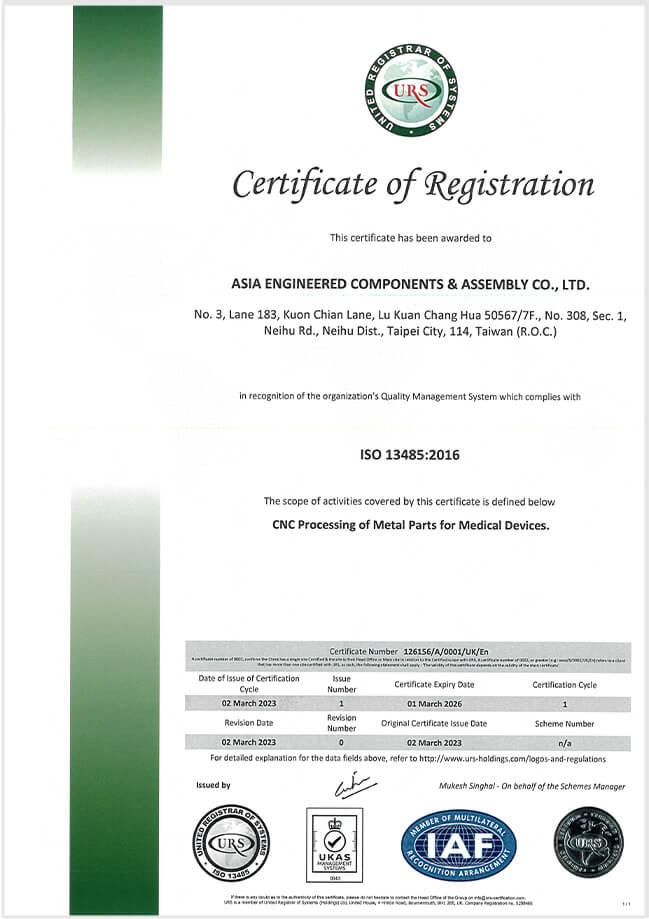

Certified by ISO 9001:2015 and ISO 13485:2016 , focusing on product quality management and medical industry compliance. Certified by IATF 16949:2016 , meeting stringent requirements for automotive component supplies.

Who We Are & What We Do

AECA specializes in high-precision CNC machining technology , integrating automated inspection and big data analysis to deliver high-quality component manufacturing services to the global market.

Expertise in processing small parts and complex precision assemblies, meeting high standards required by the automotive and medical industries. Provides end-to-end import and export services, ensuring on-time delivery and global operational capabilities.